- »

- Products »

- X-Kar »

- Superior Convection Batch Ovens »

- Bench Top Batch Ovens and Accessories »

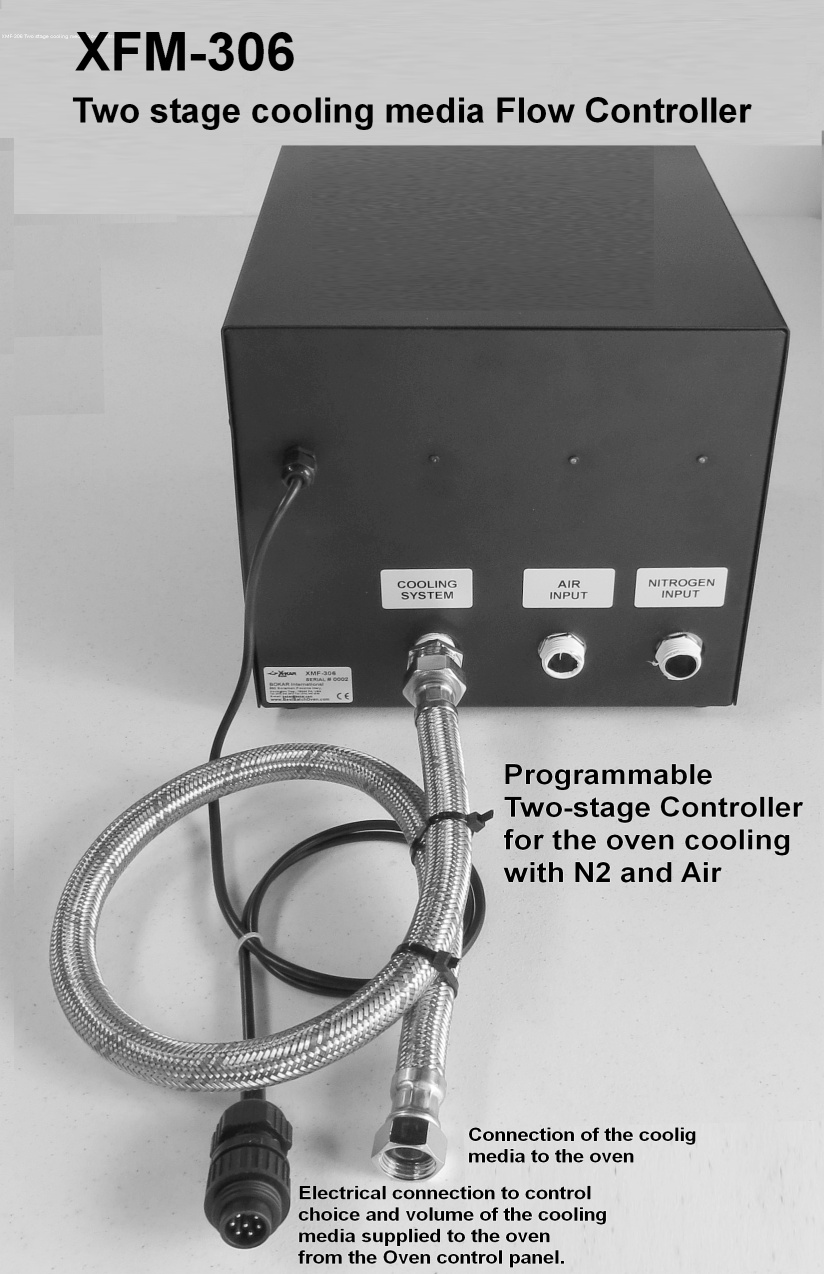

- XMF-306 Cooling Media Mass Flow Controller

XMF-306 Cooling Media Mass Flow Controller

Description

The cooling media mass flow controller is a propriatory Bokar unit developed to give the users of our Batch Convection Ovens an extraordinary tool to preset and control the rate of cooling for the objects heated in the ovens. It is a device which attaches to the Batch Oven and is controlled from the control panel of the Oven. The operator (user) can preset the cooling media (Air, N2 or both) flow volume (measured in l/min or SCFM) that will enter the oven after the end of the max heating zone to rapidly cool the hot object. There are two inputs for cooling media. One can be for N2 and the second for Air. (N2 is recommended for cooling PCB’s after reflow to quickly solidify molten solder). Volume and period of time for each Fast Cool and regular cooling cycle can be set. The cooling media mass flow controller will maintain a constant flow for a preset time and will compensate for variation of pressure entering the controlled area. Constant flow is guaranteed over input pressure changes from 4 – 8 bar. The mass flowmeter is guaranteed for 3 years and if used as intended does not require calibration. However, it is recommended to send it to the manufacturer for a calibration check once every 3 years or so.

Flow controller operation is very simple. The controller needs to be connected to the oven using the 3/4” diameter pipe supplied with the unit and the cable connector of the multi-conductor wire needs to be connected to the back panel of the oven. Also, the cooling media ½” diameter lines need to be connected to the controller input ports. If only one input is used the second can remain unconnected. Each port has a check valve preventing cooling media exiting through the unused port. All that the operator needs to do is to key in the cooling volume when entering the heating/cooling profile via the Control Panel of the oven.

Cooling rates obtained when using our controller are unmatched by anyone in the industry.

If the oven mode that adjusts heat based on air temperature is used, there is only one cooling zone.

When setting the profile, the operator can set only one mass flow volume of air or N2 (whichever is connected to the air input). (Note: The inputs are labeled N2 and Air but both gasses can be connected to the input of choice). Some users want faster cooling in the zone Cool1 and use N2 connected to N2 input, and after initial cooling use Air (which is less expensive) in zone cool2.

Technical Specifications

|

Power Requirements |

24V DC |

|

COMMAND INPUT |

1 -10V DC |

|

ANALOG OUTPUT |

1 -10V DC |

|

CALIBRATED SUPPLY PRESSURE |

0 TO 8 BAR GAUGE |

|

CALIBRATED FLOW RANGE |

4 TO 8 SCFM |

|

AIR INPUT (port size) |

1/2” |

|

NITROGEN INPUT (port size) |

1/2” |

|

COOLING SYSTEM (Connection of the cooling media to the oven -port size) |

1/2” |

|

Flow Rate Control |

8 to 80 cfm (~227 to 2265 L/min) |

|

System dimension (without the air line) |

L=12.6”xW=10”xH=9.5” (L=320mm x W=254mm x H=240mm) |

|

Weight (unpacked) |

19.9lbs. (9 kg) |

|

Packaged weight and dimension |

24.3lbs. (11 kg) |